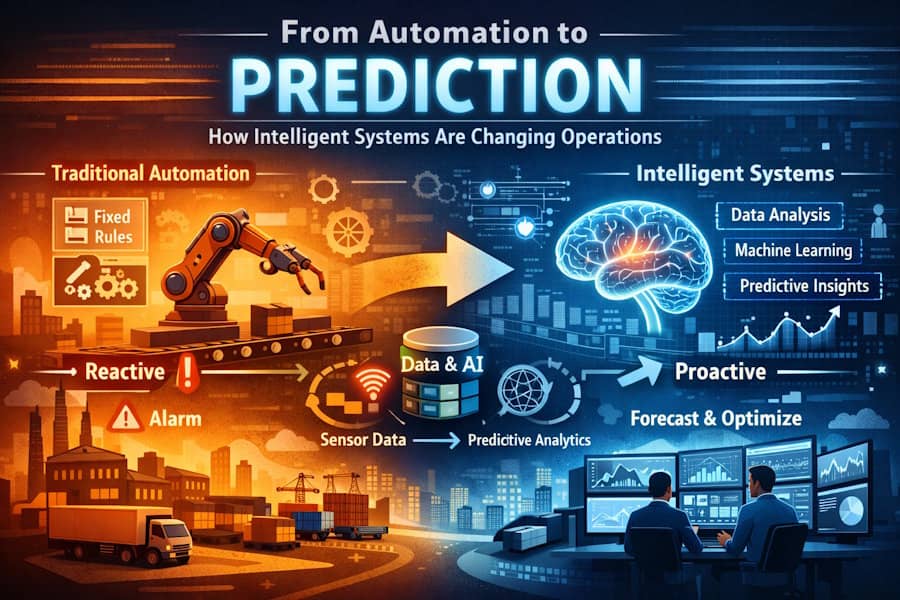

In recent decades, organizations across industries have embraced automation as a way to increase efficiency, reduce costs, and minimize human error. Automated systems transformed repetitive tasks, standardized workflows, and accelerated production lines. However, a new shift is underway. Intelligent systems are no longer limited to executing predefined rules; they are now capable of learning, adapting, and predicting outcomes. This evolution from automation to prediction is fundamentally changing how operations are designed, managed, and optimized.

At the core of this transformation is the integration of data-driven intelligence into operational processes. Modern organizations generate massive volumes of data from machines, software platforms, customers, and supply chains. Intelligent systems analyze this data in real time, uncover patterns, and provide insights that were previously inaccessible. Instead of reacting to problems after they occur, companies can now anticipate issues, optimize decisions, and plan future actions with greater accuracy.

The Limits of Traditional Automation

Traditional automation focuses on efficiency through predefined instructions. A machine or system performs tasks exactly as programmed, regardless of changing conditions. While this approach works well for stable and predictable environments, it struggles in complex and dynamic contexts. Unexpected demand fluctuations, equipment failures, or market changes often require human intervention, slowing down operations and increasing risk.

This rigidity highlighted the need for more flexible systems. Businesses began to realize that efficiency alone was not enough; adaptability and foresight were becoming equally important. As competition intensified and customer expectations rose, organizations needed systems that could not only execute tasks but also learn from experience and respond intelligently to change.

The Rise of Intelligent Systems

Intelligent systems combine advanced algorithms, machine learning models, and real-time data processing to move beyond static automation. These systems continuously analyze historical and live data, improving their performance over time. Instead of following fixed rules, they adjust their behavior based on patterns, probabilities, and contextual understanding.

In operations, this means processes become self-optimizing. Manufacturing systems can predict equipment wear before breakdowns occur. Logistics platforms can anticipate delivery delays and reroute shipments automatically. Customer service operations can forecast demand peaks and allocate resources proactively. The focus shifts from efficiency at a single moment to sustained performance over time.

From Reactive to Predictive Operations

One of the most significant changes brought by intelligent systems is the move from reactive to predictive operations. In the past, organizations responded to problems after they happened. Downtime, shortages, or quality issues were identified through reports or customer complaints. Today, predictive models detect early warning signs long before disruptions become visible.

Predictive maintenance is a clear example. Sensors embedded in machinery collect data on vibration, temperature, and usage patterns. Intelligent systems analyze this data to identify anomalies that signal potential failures. Maintenance teams can intervene at the optimal moment, reducing downtime and extending equipment lifespan. This approach not only lowers costs but also increases operational reliability.

Decision-Making Enhanced by Intelligence

Operational decision-making has traditionally relied on experience, intuition, and static reports. While valuable, these methods are limited by human capacity and delayed information. Intelligent systems enhance decision-making by providing real-time insights and scenario-based predictions.

For example, in supply chain management, intelligent systems evaluate variables such as supplier performance, transportation costs, weather conditions, and market demand. They generate forecasts and recommendations that help managers choose the most efficient and resilient strategies. Over time, these systems learn from outcomes, continuously refining their predictions and recommendations.

This shift does not eliminate human judgment. Instead, it augments it. Leaders gain access to deeper insights, allowing them to focus on strategic decisions rather than operational firefighting. The result is faster, more informed, and more consistent decision-making across the organization.

Operational Agility and Scalability

As businesses grow and expand into new markets, operational complexity increases. Intelligent systems play a critical role in enabling scalability without proportional increases in cost or risk. By automating analysis and prediction, organizations can manage larger volumes of transactions, customers, and assets with greater precision.

Operational agility is another key benefit. Intelligent systems help organizations adapt quickly to changing conditions, whether driven by market trends, regulatory changes, or unexpected disruptions. During periods of uncertainty, predictive insights become especially valuable, allowing companies to adjust strategies proactively rather than react defensively.

This adaptability aligns closely with broader discussions around future trends in artificial intelligence, where intelligence is increasingly embedded into everyday business operations, shaping how organizations plan and compete.

Human Roles in Intelligent Operations

As intelligent systems take on more analytical and predictive tasks, human roles are also evolving. Rather than focusing on repetitive activities, professionals are shifting toward oversight, interpretation, and strategic planning. Skills such as critical thinking, cross-functional collaboration, and ethical judgment are becoming more important.

Intelligent systems require human guidance to define objectives, validate outputs, and ensure responsible use. Transparency and accountability remain essential, particularly in high-impact operational decisions. Organizations that successfully integrate intelligence into operations invest not only in technology but also in workforce development and change management.

Challenges and Considerations

Despite their benefits, intelligent systems introduce new challenges. Data quality is critical; inaccurate or biased data can lead to flawed predictions. Integration with legacy systems can be complex, requiring careful planning and execution. Additionally, organizations must address concerns related to security, privacy, and governance.

Another consideration is trust. For predictive systems to be effective, users must trust their recommendations. This requires clear explanations of how predictions are generated and ongoing validation of results. Building this trust takes time but is essential for widespread adoption.

A New Operational Paradigm

The transition from automation to prediction represents a fundamental shift in how operations are managed. Intelligent systems transform data into foresight, enabling organizations to anticipate challenges, optimize performance, and create resilient processes. Rather than simply doing things faster, businesses are learning to do things smarter.

As intelligent systems continue to evolve, their role in operations will only expand. Organizations that embrace this shift position themselves to thrive in increasingly complex and competitive environments. By combining predictive intelligence with human expertise, they unlock new levels of efficiency, agility, and strategic advantage, redefining what operational excellence means in the modern era.