Maintenance managers are responsible for ensuring that facilities and equipment are adequately maintained. In companies that have a lot of maintenance tasks managing maintenance, the manager is often daunting without a CMMS (computerized maintenance management software). A powerful CMMS comes with tools that help you manage your maintenance activities, track any issues, and suggest areas to improve.

Efficient maintenance management is crucial for any organization, and that's where computerized maintenance management software (CMMS) comes in. When choosing a CMMS, it's important to look for key features that can help streamline your maintenance processes. For example, a good CMMS should be able to keep track of your assets like spare parts and equipment, store warranty and supplier information, and provide data on life expectations. Additionally, some CMMS may also have features for vendor management and contract management systems that can further enhance your maintenance management capabilities. If you're interested in learning more about contract management systems, you can find more information by clicking here.

What Exactly Is Computerized Maintenance Management Software (CMMS)?

A computerized Maintenance Management System, also known as a CMMS, is a software system that consolidates maintenance data and assists in maintenance activities. It can help optimize the use and availability of physical equipment such as vehicles and machinery, communications plant infrastructures, and other assets. In addition, effective CMMS implementations can enhance ESP and HPS operations monitoring and optimization, ensuring that all maintenance processes are streamlined and efficient.

Also known by CMMIS as a computerized management system for information, CMMS systems are used in the manufacturing industry, energy production, oil and gas power generation construction, transportation, and other sectors in which physical infrastructure is crucial.

The heart of the CMMS will be its database. It's got an organized data model that stores data about the assets a maintenance organization is responsible for maintaining, in addition to the equipment and materials for doing so.

For seamless management of your assets, consider incorporating a computerized Maintenance Management System (CMMS), which plays a pivotal role in optimizing equipment utilization across various sectors. Click for RightAngle Support and Maintenance to enhance the efficiency of your CMMS and ensure the smooth operation of your critical infrastructure.

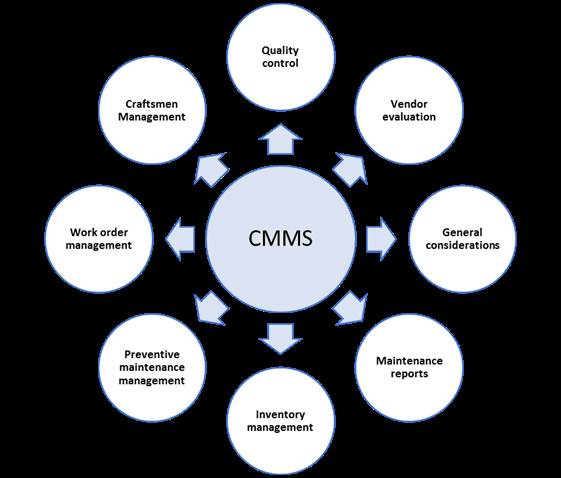

What Functions Does A CMMS Contain?

When choosing software, there are many things a facility manager should consider before purchasing one. In that case, it will have basic features that any top-quality maintenance management software will come with, including work order management, scheduled maintenance planning inventory management, asset management, maintenance reports, and a mobile application.

Utilizing these features of CMMS will allow you to deal with the majority of your maintenance challenges. Imagine the problems your maintenance team has to face every day. Backlogs, breakdowns, missing parts, and cost overruns - the list is endless. You can access a highly effective tool to alleviate these issues if you have CMMS software.

Asset Management

Equipment and assets come in regular use; that's the reason they wear and wear! They then require maintenance. A wealth of asset information in the palm of your fingers is a tremendous benefit.

CMMS provides information about the condition and condition of your asset in real-time. Companies require a plan to extend the life of assets, and CMMS assists in fulfilling this goal.

In addition, asset misplacement, theft of assets, and misuse of assets are also prevented with CMMS since it assists in tracking assets. In general, CMMS provides a clear 360-degree overview and centralized information on assets to help inefficient assets management.

Work Order Management

One of the skills for maintenance worker is to scheduler work orders. A CMMS can create work orders according to established maintenance schedules and respond to requests for fixes made by staff members who have been approved.

CMMS work order features assist maintenance workers in sorting out work orders according to the priority of the work order. Each request is assigned several requests, which the support team can quickly identify.

From submitting a request for work to scheduling, planning, and completing the work demand, CMMS consistently tracks the progress of the work and ensures timely and efficient delivery of work.

After that, using the CMMS program, the technicians can create an accurate record of the processed maintenance activity. Furthermore, the CMMS work order permits you to quickly react when a breakdown of an asset and prioritize work orders to keep your facility efficient and efficient.

Reporting & Analysis

When you input information into your CMMS, it is accessible for any analysis or reports you require. The information about assets is added to the database and any issue it detects automatically sends out an alert to the supervisor in charge of maintenance. The alert also provides suggestions for solutions.

After the task is finished, the technician then enters details of the job, the duration, components or materials used during the repair, and the labor information. The system uses the information provided to aid in future repair and maintenance schedules.

Preventive Maintenance

If you have a solid preventive maintenance (PM) program in place, you can be sure that you're doing everything you can to extend the usefulness and longevity of your assets for the business. The most significant benefits of this type of program are reducing the cost of emergency repairs and stopping the deterioration of assets.

Asset Management

A profitable and effective business is dependent on two factors organizational machinery and equipment. They aid in making products, but they also help customers and offer worth. Any equipment malfunction could impact your company's operations. In the event of losing the equipment, it could be lost.

The item or even theft of assets are additional factors that can significantly impact the value and performance of the company's assets. The tracking of these metrics will benefit you tremendously. The features you could include in your asset management and equipment software include:

-

Repair history

-

Work orders access to pictures, warranties information, and meter readings

-

Floor plan management

Vendor Management

A well-functioning CMMS can assist an association in managing vendor and asset management. If employees require an inventory, the system has created templates that will save employees' time. They do not need to look elsewhere for locations to locate request forms. The system also keeps up-to-date on the work order, like when the order has been processed at the end of the vendor's day.

CMMS system keeps track of orders to determine when the order is complete, and the individual is fully aware of every order. It keeps track of the order by the shipment status and real-time information.

When a new order is made to the vendor, the vendor is notified. In the case of managing vendors of the system, CMMS helps provide upkeep managers immediate access to data about vendors, including contact information.

Mobile CMMS

Mobile devices are now an essential part of the lives of every individual and company. If your CMMS solution doesn't offer complete mobile compatibility as a competitive option to modernize your maintenance management, you'll miss out on lots.

It is common to experience facilities maintenance and inventory maintenance issues in real-time. This means it is crucial to access your data via a mobile device, like a smartphone or tablet. This allows you to keep track of any issues at any time of the day, no matter the location you are in. Make sure your vendor offers an interface for responsive mobile devices or a native mobile application.