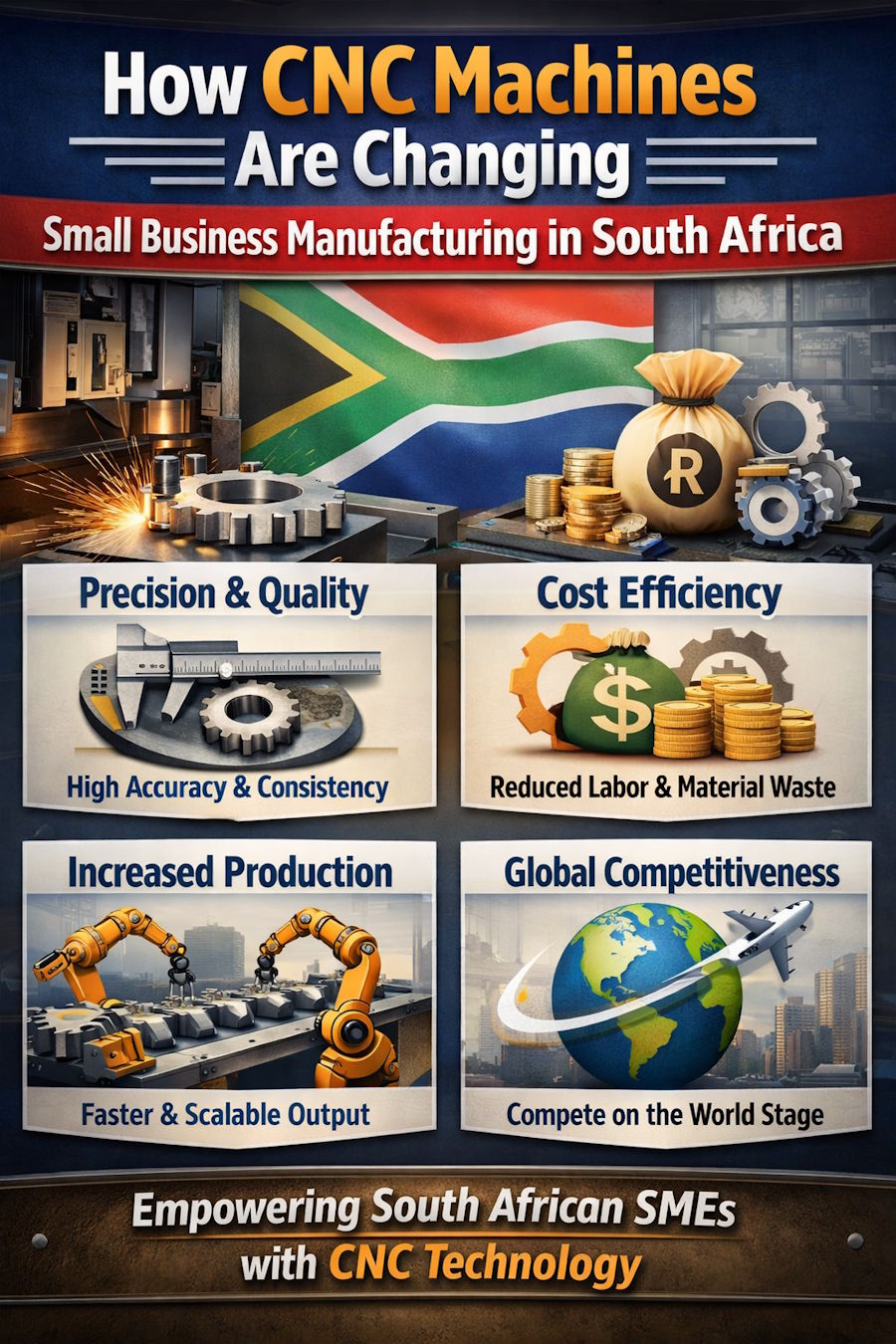

In the heart of South Africa's industrial landscape, a technological revolution is quietly transforming small manufacturing businesses. CNC (Computer Numerical Control) machines are rewriting the rules of production, giving local entrepreneurs unprecedented power to compete globally. From Cape Town's workshop to Johannesburg's industrial zones, these precision tools are becoming the backbone of a new manufacturing era, enabling small businesses to achieve levels of quality and efficiency once reserved for large corporations.

What Are CNC Machines and Why Are They Important for Small Businesses?

CNC machines represent a quantum leap in manufacturing technology, bridging the gap between human skill and computer-driven precision. At their core, these machines use computer programming to control tools and machinery with microscopic accuracy, allowing manufacturers to create complex parts and components with unprecedented consistency. According to am.co.za for South African small businesses, CNC technology means breaking free from traditional manufacturing limitations. These machines can transform raw materials into intricate designs with minimal human intervention, reducing labor costs and eliminating human error.

The fundamental power of CNC machines lies in their ability to translate digital designs directly into physical products. Unlike traditional manual manufacturing, where a craftsman might spend hours creating a single component, CNC machines can reproduce identical parts with remarkable speed and precision. This capability is particularly revolutionary for small businesses in South Africa's competitive manufacturing sector, where efficiency and quality can make the difference between success and failure.

How CNC Technology Works?

CNC technology operates through a sophisticated system of computer-controlled movements and instructions. Imagine a highly intelligent robot that can cut, shape, and manipulate materials with laser-like precision.

The experts at Machine Affrica explain the process begins with a digital design created using Computer-Aided Design (CAD) software. This digital blueprint is then converted into a language that CNC machines understand, called G-code. This code provides exact instructions for every movement, including cutting depth, speed, and direction.

The machine's cutting tools move along multiple axes - typically X, Y, and Z - allowing for three-dimensional manufacturing. This multi-axis capability means that complex geometries can be created in a single setup, dramatically reducing production time. For a small South African manufacturer, this translates to faster turnaround times and the ability to take on more complex projects that were previously impossible or prohibitively expensive.

Why Small Manufacturers in South Africa Are Adopting CNC Machines Faster

South African small manufacturers are embracing CNC technology due to mounting competitive pressures and the need for global market relevance. The local manufacturing landscape has become increasingly challenging, with global competition and economic uncertainties pushing businesses to innovate. CNC machines offer a strategic solution by enabling smaller workshops to produce high-quality products that meet international standards.

Local industries like automotive components, aerospace parts, and precision engineering are seeing rapid CNC machine adoption. By investing in this technology, small businesses can reduce production costs, minimize material waste, and increase overall efficiency. The ability to quickly prototype and produce complex parts gives South African manufacturers a competitive edge, allowing them to compete with larger, more established international manufacturers.

Key Benefits of CNC Machines for Small Manufacturing Businesses

Precision is the most significant advantage of CNC machines for small businesses. Traditional manufacturing methods rely heavily on manual skills, which can vary between workers. CNC machines eliminate this variability, producing components with tolerances as tight as 0.01mm. For industries requiring extremely precise parts - like medical equipment or aerospace components - this level of accuracy is game-changing.

Reduced waste is another critical benefit. CNC machines optimize material usage through precise cutting strategies, significantly lowering raw material costs. A small manufacturing business can save up to 30% on material expenses by minimizing excess waste. Additionally, these machines operate with consistent quality, meaning every produced part matches the original design exactly. This consistency builds trust with clients and reduces the likelihood of costly product returns or rework.

How to Select the Right CNC Machine for Your Small Business Needs

Selecting an appropriate CNC machine requires careful consideration of specific business needs, budget, and production requirements. Entry-level CNC machines for small workshops might start around R150,000, while more advanced models can cost over R1 million. Factors like machine size, cutting capabilities, and software compatibility play crucial roles in the selection process.

Small businesses should consider their primary manufacturing needs: metal cutting, woodworking, or multi-material processing. Some machines specialize in specific materials, while others offer versatility. Consulting with local equipment suppliers and attending manufacturing technology exhibitions can provide valuable insights into making the right investment.

Is CNC Manufacturing Affordable for SMEs?

While initial CNC machine investments might seem substantial, the long-term financial benefits are significant. A typical small business can recover its investment within 18-24 months through increased productivity and reduced labor costs. The machines operate with minimal human supervision, allowing staff to focus on higher-value tasks like design and client relationships.

Government incentives and financing options are making CNC technology more accessible. The South African Department of Trade and Industry offers various support mechanisms for small manufacturers investing in advanced technologies. Leasing options and equipment financing programs help businesses spread the initial investment over manageable periods, making CNC machines increasingly attainable.

How CNC Machines Help Businesses Scale Faster

CNC machines enable small manufacturers to dramatically increase production capacity without proportionally increasing workforce or workspace. A single machine can often replace multiple workers, operating continuously with minimal breaks. For instance, a small engineering workshop in Durban reported increasing production output by 200% after implementing CNC technology.

The scalability potential is immense. Businesses can quickly adapt to market demands by reprogramming machines for different product designs. This flexibility allows manufacturers to diversify their product range without significant additional investment, creating new revenue streams and market opportunities.

Future of Small Business Manufacturing in South Africa with CNC Technology

The future of South African manufacturing is intrinsically linked to CNC technology adoption. As global markets become more competitive, small businesses that invest in these advanced manufacturing tools will be better positioned to succeed. The ongoing technological advancements promise even more accessible, efficient, and sophisticated CNC solutions in the coming years.

Integration with emerging technologies like artificial intelligence and advanced robotics will further enhance CNC machine capabilities. South African manufacturers who stay ahead of these technological curves will create sustainable, competitive businesses capable of serving both local and international markets.

Final Thoughts

- CNC machines offer unprecedented precision and consistency in manufacturing

- Initial investments can be recovered within 18-24 months through increased productivity

- Technology enables small businesses to compete on global quality standards

- Reduced material waste and labor costs provide significant financial benefits

- Ongoing technological advancements make CNC machines increasingly accessible

- Flexible manufacturing capabilities allow rapid product design changes

- Government support and financing options are available for technology investment