Construction projects these days call for speed, accuracy, and economic management at every stage. Traditional cloth calculation techniques regularly fall behind in keeping pace with modern-day mission complexity, leading to delays, remodels, and price overruns. This is where automation-pushed solutions are remodeling how expertsapproache fabric planning.

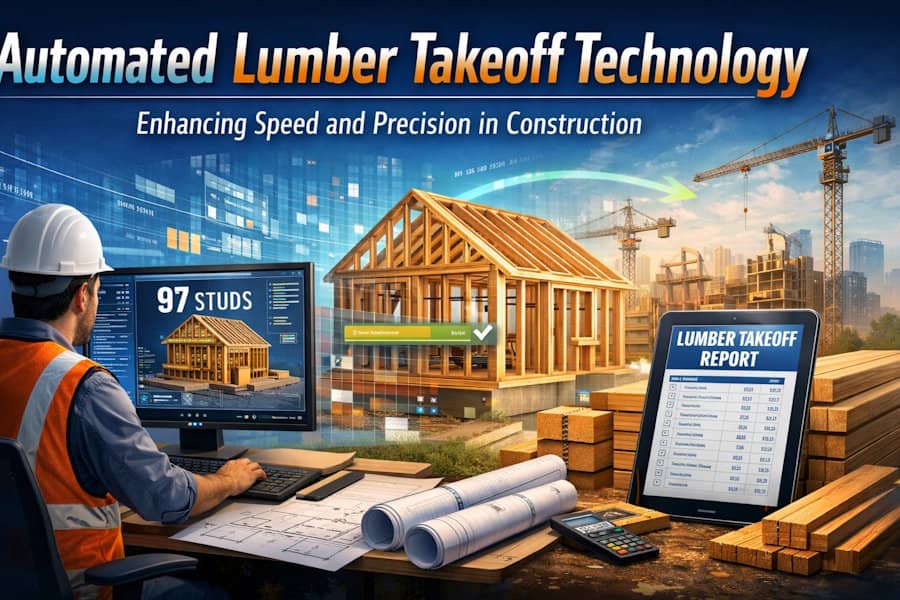

Automated lumber takeoff technology introduces a better manner to calculate portions, minimize waste, and improve coordination between layout and execution. By replacing manual spreadsheets and visual guesswork with clever structures, teams can make faster decisions while retaining precision. As digital adoption grows, this era is turning into a foundational detail of efficient production workflows.

The Shift From Manual Methods to Intelligent Quantity Automation

For decades, contractors depended on hand measurements, published drawings, and manual calculations to estimate wood requirements. While this approach worked well for smaller tasks, it frequently introduced human errors in large or rapidly tracked trends. Even a minor miscalculation could result in cloth shortages or highly-priced overordering.

Automation modifies this process totally by means of extracting measurements without delay from digital plans. Instead of estimating the board with the aid of the board, the system evaluates dimensions, spacing, and structural necessities in seconds. This extensively reduces the chance of oversight while improving consistency throughout projects.

Within this evolution, LUMBER TAKEOFF performs a crucial function by using enabling specific amount extraction that aligns with actual-international construction requirements. The result is a streamlined workflow that supports faster approvals, clearer documentation, and higher cost predictability without relying on repetitive manual effort.

How Automation Improves Speed, Accuracy, and Cost Control

One of the most valuable advantages of computerized systems is their capacity to balance pace with accuracy. Instead of spending days reviewing drawings, estimators can generate specified quantity reports within hours. This lets project teams respond fast to bid opportunities and design adjustments.

Accuracy improves because calculations are primarily based on exact dimensions as opposed to assumptions. Automated structures also practice predefined regulations for waste factors, spacing, and fabric grades, making sure consistency throughout estimates.

Example Calculation (Mid-Article)

Consider a residential framing task:

Wall period: one hundred twenty linear feet

Stud spacing: sixteen inches (1.33 feet)

Stud height: nine ft

Manual estimation approach:

120 ÷ 1.33 ≈ 90 studs (rounded)

Automated technique:

The machine calculates:

Exact stud count number based on openings

Adds 8% waste element robotically

Final output: 97 studs

This degree of detail helps keep away from shortages on site and prevents extra shopping, directly improving price range management and fabric usage.

Supporting Professional Estimation and Project Coordination

Automation no longer replaces professionals; it complements their competencies. Estimatorshave the advantage of extra time to research information, check risks, and offer strategic input rather than repeating repetitive calculations. This shift improves overall assignment coordination and conversation among stakeholders.

Digital amount outputs integrate effortlessly with pricing databases and scheduling gear. This approach updates drawings and can instantly replicate in cloth quantities, preserving all people aligned. For organizations running as a Construction estimating Company, automation supports scalability with the aid of maintaining accuracy across multiple projects without growing workload stress.

By relying on based virtual facts in place of individual judgment alone, teams can deliver more consistent outcomeswhiles building consideration with customers and partners.

Read more: Dimensional 2×6 Lumber Sizes Applied in Building and Remodeling of Home

Long-Term Value for Sustainable and Scalable Construction

Beyond immediate efficiency, automated lumber takeoff generation contributes to long-term sustainability desires. Accurate calculations reduce waste, lower transportation charges, and restrict needless cloth waste. This directly helps environmentally responsible construction practices.

Scalability is aanotherpredominant advantage. Whether coping with a single residential venture or a multi-segment business development, automatic structures adapt without difficulty without sacrificing precision. When paired with Construction estimating services, this era ensures that estimates remain reliable whilst task length and complexity boom.

Over time, businesses that undertake automation gain an aggressive edge via faster turnaround, improved margins, and stronger business outcomes.

Final Thoughts

Automated lumber takeoff generation is no longer a future idea; it's miles an vital tool for modern production success. By combining pace, precision, and data-driven accuracy, it addresses lengthy status-demanding situations in material estimation and cost control. As projects develop more complicated and timelines tighten, automation empowers professionals to deliver dependable outcomes while preserving efficiency and sustainability. Embracing this generation is not pretty much retaining up—it’s about building smarter, faster, and more confidently.

Frequently Asked Questions

- How does automated lumber takeoff improve accuracy?

It calculates quantities directly from digital plans using predefined rules, reducing human error and inconsistencies. - Can automated systems handle design changes easily?

Yes, updated drawings can be reprocessed instantly, providing revised quantities without starting from scratch. - Is automated takeoff suitable for small projects?

Absolutely. It saves time and improves precision regardless of project size. - Does automation increase upfront costs?

While there may be initial setup costs, long-term savings from reduced waste and faster workflows often outweigh them. - How does automation support sustainability?

Minimizing overordering and material waste, it helps reduce environmental impact and supports responsible construction practices.