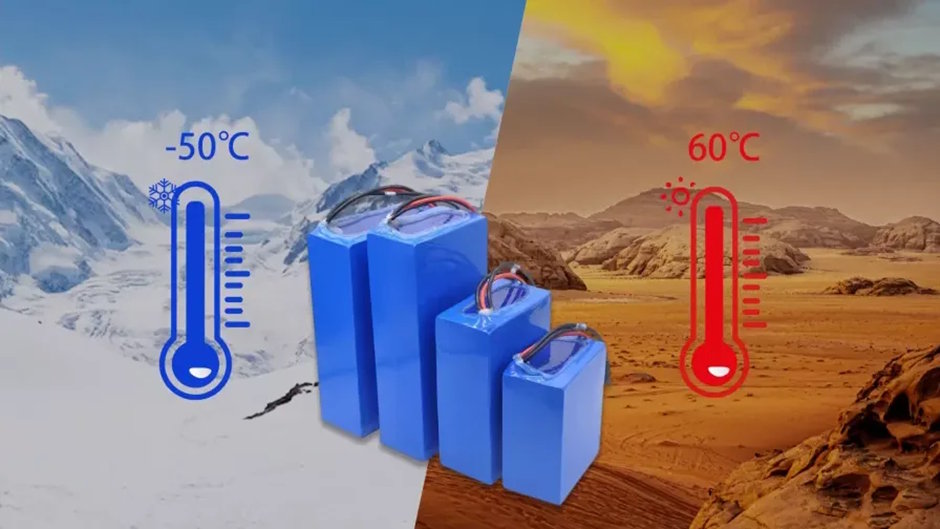

Lithium battery low temperature performance plays a critical part in operations that operate in harsh and cold surroundings. When temperatures drop, lithium batteries witness reduced capacity, slower charging rates, and advanced internal resistance, which directly affects trustability and safety.Diligence similar as artificial robotization, robotics, out-of-door monitoring and communication systems, UAVs operating at high mound or polar regions, and deep- ocean outfit decreasingly depend on low temperature lithium ion battery results to maintain stable operation.A low temperature battery is specifically designed to serve in surroundings as cold as-40 °C. This composition discusses how low temperatures affect battery geste, why charging in cold conditions is perilous, and how lithium battery low temperature protection and BMS design help insure safe and harmonious performance.For practical exemplifications of cold- resistant battery systems, you can relate to this result

https//cmbatteries.com/project/low-temperature-battery/

How Low Temperature Affects Lithium Battery Performance

Capacity Degradation

At low temperatures, chemical responses inside the battery laggardly down and lithium- ion prolixity within electrode accoutrements becomes limited. As a result, available capacity drops significantly. At-20 °C, a lithium battery may retain only about 60 of its room- temperature capacity, while at-40 °C, capacity can fall below 5.

Increased Internal Resistance

Cold conditions increase electrolyte density and reduce ion conductivity. This raises internal resistance, limits affair power, and causes brisk voltage drop during discharge. In electric vehicles and artificial outfits, this leads to weaker performance and reduced effectiveness.

Reduced Charging and Discharging effectiveness

Low temperatures circumscribe lithium- ion intercalation and deintercalation. Charging becomes slower and less effective, while discharge voltage declines more fleetly. For example, charging effectiveness at-20 °C may drop to around 65% in normal situations.

Advanced Safety pitfalls

Charging at low temperatures increases the threat of lithium plating on the anode face. This can lead to lithium dendrite conformation, which may perforate the division and beget internal short circuits, potentially performing in fire or explosion.

Docked Cycle Life

Long- term operation in cold surroundings accelerates internal declination processes similar as SEI subcaste thickening and active material loss, leading to unrecoverable capacity fade and reduced cycle life.

Why Lithium Batteries Should Not Be Charged at Low Temperatures

Limited Lithium- Ion Migration

Low temperatures increase electrolyte resistance, decelerating lithium- ion movement during charging. This significantly reduces charging effectiveness and extends charging time. At-20 °C, charging effectiveness may drop to roughly 65.

threat of Lithium Dendrite conformation

When lithium ions can not duly fit into the anode, they may deposit on the face as metallic lithium. These deposits reduce battery capacity permanently and increase the threat of internal short circuits and safety failures.

LiFePO4 vs Sodium- Ion Battery Performance at Low Temperatures

In cold surroundings, LiFePO4 battery low temperature performance is generally weaker than that of some sodium- ion battery designs. Still, lithium iron phosphate batteries offer high stability, mature manufacturing processes, and fairly high energy viscosity, making them suitable for numerous artificial operations.Sodium- ion batteries frequently demonstrate more Low temperature battery performance, but they presently have lower energy viscosity and shorter cycle life. As a result, they're more suitable for operations where cold- rainfall performance is prioritized over compact size or long abidance.

Low- Temperature Discharge Performance

Lithium Iron Phosphate Batteries

At-20 °C, LiFePO4 batteries may lose 30 – 50 of their capacity. Reduced conductivity of the cathode material, slower lithium- ion prolixity, and increased electrolyte density each contribute to advanced internal resistance.

Sodium- Ion Batteries

Some sodium- ion batteries maintain 70 – 90 capacity at-20 °C. Their electrochemical characteristics allow more effective ion transport at low temperatures, especially when optimized electrolyte phrasings are used.

Low- Temperature Charging Performance

Lithium Iron Phosphate Batteries

Charging LiFePO4 batteries in cold conditions increases the liability of lithium plating. To reduce this threat, charging currents are generally limited or battery heating systems are actuated before charging begins.

Sodium- Ion Batteries

Sodium- ion batteries show a lower tendency for dendrite conformation and may retain limited charging capability at low temperatures. Still, charging speed is still reduced compared to room- temperature conditions.

Lithium Battery Low Temperature Protection and BMS Design

Effective lithium battery low temperature protection depends on a well- designed Battery Management System( BMS). By combining accurate temperature seeing, adaptive heating strategies, and intelligent control sense, BMS results help maintain battery safety and performance in cold surroundings.

crucial Design Points of BMS Low- Temperature Protection

Temperature Monitoring and Threshold Control

Multiple temperature detectors continuously cover battery conditions. Protection thresholds, generally between 0 °C and 5 °C, acclimate stoutly grounded on battery chemistry and operation conditions.

Heating Strategy Design

- Preheating

The BMS activates hotting rudiments similar to PTC heaters to raise battery temperature above 10 °C before charging. - Heating Control Logic

Heating power and duration are acclimated to balance energy consumption and heating effectiveness.

Charging and Discharging Optimization

- Charging

Charging current is reduced or temporarily broken at low temperatures. - Discharging

Affair power is acclimated to help damage caused by high current draw in cold conditions.

Overall BMS Design Architecture for Low- Temperature Protection

Hardware Design

- High- delicacy voltage, current, and temperature detectors

- Automotive- grade MCUs for control and protection sense

- Low- loss MOSFETs and power factors to insure dependable operation

Software Algorithms

- SOC and SOH estimation using coulomb counting and Kalman filtering

- Cell balancing strategies to reduce voltage imbalance

- Real- time fault discovery and canted protection mechanisms

Safety and Reliability Design

Redundancy

Critical factors similar to temperature detectors and relays are designed with redundancy. Binary- MCU infrastructures ameliorate overall system trustability.

Communication and System Integration

The BMS communicates with external control systems through CAN FD or Ethernet, enabling real- time monitoring, remote diagnostics, and OTA updates.

Companies Specializing in Lithium Batteries for Cold surroundings

Low temperatures can significantly reduce lithium battery effectiveness without proper thermal operation. Artificial battery packs frequently integrate heaters or tone- heating technology to maintain stable operation.For illustration, CM Batteries provides customized LiFePO4 and sodium- ion battery packs designed for cold- climate operations. These results are extensively used in robotics, out-of-door monitoring, UAVs, and energy storehouse systems where dependable low- temperature performance is essential.

https://cmbatteries.com/