Introduction

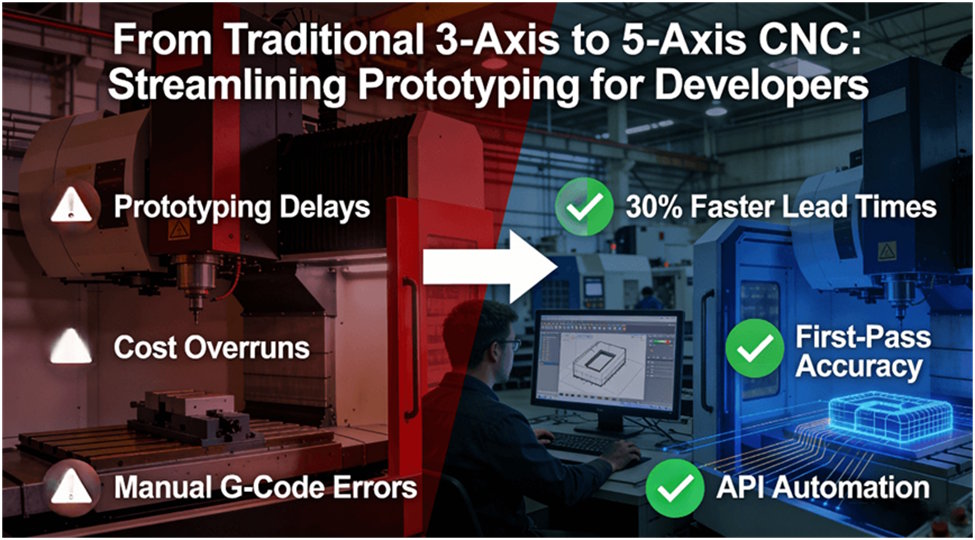

In software-driven manufacturing, developers frequently face prototyping delays and cost overrunsdue to incompatibilities between traditional CNC programming and complex designs, necessitating multiple iterations. The core issue stems from the inherent limitations of 3-axis CNC systems, which lack multi-angle machining capabilities and often require manual G-code adjustments, increasing error risks. Furthermore, insufficient CAD/CAM integrationexacerbates these challenges, leading to inefficient workflows.

This article demonstrates how 5-axis CNC machining services, enhanced by automated APIs and precision programming, streamline prototyping to ensure first-pass accuracy. Referencing standards like ASME Y14.5, we outline a methodology to reduce lead times by 30%. The following sections delve into best practices for integrating 5-axis technology with software-driven processes, empowering developers to optimize manufacturing efficiency.

What Is 5-Axis CNC Machining and How Does It Differ from Traditional Methods?

5-axis CNC machining introduces two rotational axes (e.g., A and C) alongside linear XYZ motions, enabling dynamic tool orientation. This advanced kinematic controlfundamentally diverges from 3-axis constraints, unlocking new possibilities for complex geometries.

1. Fundamental Principles of Multi-Axis Motion

The simultaneous movementof five axes allows tools to maintain optimal engagement angles with contoured surfaces. For instance, while machining a turbine blade, the tool can continuously adjust its orientation to avoid collisions and ensure uniform cutting forces. This dynamic capabilityeliminates the need for multiple setups, reducing cumulative errors cited in ASME Y14.5 standards. To fully utilize the potential of 5-axis CNC machining services, a thorough understanding of its working principles is essential.

2. Limitations of 3-Axis Systems for Complex Designs

Traditional 3-axis machiningstruggles with deep cavities and undercuts due to linear toolpaths, often requiring partial machining and repositioning. This manual interventionintroduces misalignment risks, leading to scrap rates up to 15% for intricate parts. Additionally, ball-end tool inefficiencyon curved surfaces causes rubbing rather than cutting, accelerating wear. These constraints highlight the necessity for advanced 5-axis solutions.

3. Advantages of Single-Setup Machining

By completing parts in one clamping, 5-axis systems eliminate repositioning errors, ensuring features like threaded holes and angled faces maintain positional accuracy within ±0.01mm. A case study on drone motor mounts showed a 40% reduction in machining time and a 25% improvement in concentricity. This integrated approachis pivotal for high-precision applications.

Why Is Precision Manufacturing Programming Critical for 5-Axis CNC Efficiency?

Effective CAD/CAM developmenttranslates digital designs into precise toolpaths, minimizing manual coding errors. The synergy between software and hardware dictates prototyping success.

l G-Code Optimization and Path Planning: Advanced CAM softwaregenerates efficient G-code by simulating material removal, optimizing parameters like feed rates and spindle speeds. For example, adaptive toolpathsreduce cycle times by 20% while extending tool life. However, manual G-code editingremains error-prone; a single miscalculation can damage tools or scrap expensive materials. Automating this through precision manufacturing programmingis therefore critical.

l CAD/CAM Integration for Complex Geometries: Seamless data exchangebetween CAD and CAM systems ensures design intent is preserved. Software like Siemens NX converts 3D models into machine instructions, incorporating tilt angles and lead settingsfor 5-axis operations. In medical implant prototyping, this integration reduced programming time from 8 hours to 90 minutes, accelerating iterations. This underscores the value of robust CAD/CAM development.

l Real-Time Simulation and Error Prevention: Virtual machining environmentsdetect collisions and inefficiencies before physical production. A developer using simulation tools avoided a 15% scrap rate by identifying toolholder interference in a complex housing. This proactive validationis indispensable for first-pass accuracy.

How Can Industrial Automation APIs Integrate with 5-Axis CNC Systems for Seamless Prototyping?

Industrial automation APIsbridge software applications and CNC machinery, enabling real-time data exchange and process control. This integration is transformative for agile manufacturing.

1. RESTful API Applications for Direct Machine Control

RESTful APIsallow developers to send design files (e.g., STEP formats) directly to CNC controllers, bypassing manual uploads. For instance, a cloud-based platformreduced pre-processing time by 60% by automating file conversions. This streamlined workflowis particularly beneficial for rapid prototyping cycles.

2. Customization for Open-Source Hardware Projects

Open-source hardware projects, such as custom Raspberry Pi enclosures, leverage APIs to program intricate features without extensive coding. Libraries like PyCNC facilitate G-code generationfrom Python scripts, making complex part 5-axis machiningaccessible to developers. This flexibility supports innovation in community-driven initiatives.

3. Data-Driven Process Optimization

API-enabled monitoringcollects real-time data on tool wear and machine performance, triggering maintenance alerts. A IoT-integrated system cut downtime by 25% through predictive analytics, demonstrating how industrial automation APIecosystems enhance reliability.

What Factors Influence an Accurate 5-Axis CNC Machining Quote?

Transparent quotinghinges on quantifying design complexity, material selection, and quality requirements. A data-driven approach avoids budget surprises.

1. Design Complexity and Machining Time

Geometric intricacieslike thin walls or deep pockets increase programming and cycle times. For example, a part with free-form surfacesrequired 18 hours of machining versus 6 hours for a prismatic design, impacting cost by 200%. Suppliers analyze CAD models to estimate these factors accurately, forming the basis of a 5-axis CNC machining quote.

2. Material Selection and Tooling Costs

High-performance materialslike titanium incur higher expenses due to specialized tooling and slower speeds. However, aluminum alloyscan reduce costs by 30% while maintaining strength for prototypes. ISO 9001-certified suppliers provide detailed breakdownsto justify quotations, ensuring alignment with project goals.

3. Quality Standards and Certifications

Tight tolerances(e.g., ±0.025mm) and surface finish requirements(e.g., Ra 0.4μm) necessitate advanced inspection equipment, adding to costs. Compliance with standards like AS9100D for aerospace components ensures reliability but involves rigorous documentation. Understanding how to get a CNC machining quotethat includes these elements is key to budgeting.

How to Select a 5-Axis CNC Machining Supplier for Hardware Integration Projects?

Choosing a partner with technical expertiseand robust infrastructureensures project alignment with design and timeline objectives.

1. Technical Capability Assessment

Evaluate equipment portfoliosfor multi-axis machines with torque tables and high-speed spindles (e.g., 20,000 RPM). Review case studiesinvolving similar complexities, such as impellers or biomedical devices. For instance, a supplier’s experience with titanium aerospace partsdemonstrated capability to handle heat-resistant materials, a critical factor for high-stakes applications.

2. Certification and Quality Systems

Preference is given to suppliers who have obtained ISO 9001, AS9100D, or IATF 16949 certification, as these certifications ensure process consistency. For example, a company's IATF 16949 certification ensures compliance with the precision and traceability standards of the automotive industry. These certifications help mitigate risks in regulated industries.

3. Communication and Support Services

API integration supportand design feedback(DFM) are indicators of a collaborative partner. A developer reported a 30% reduction in revisions due to a supplier’s proactive suggestionson draft angles. This technical synergyaccelerates project momentum, making supplier selectiona strategic decision.

Can Open-Source Hardware Projects Benefit from Advanced 5-Axis CNC Machining?

Open-source initiativesleverage 5-axis CNC for low-volume, high-precision components, merging accessibility with industrial-grade quality.

- Cost-Effective Customization: Batch optimizationallows small teams to produce complex parts economically. A robotics group used nesting softwareto mill 10 actuator mounts from a single aluminum block, cutting unit costs by 40%. This scalabilitymakes5-axis CNC machining servicesviable for prototypes.

- Community-Driven Innovation: Platforms like GitHubhost CAD libraries for components like sensor mounts, which 5-axis CNC can reproduce with micron-level accuracy. This democratizes manufacturingwhile maintaining industrial standards, bridging the gap between hobbyist and professional projects.

- Sustainability Through Localized Production: Distributed manufacturingreduces shipping emissions and lead times. A university project produced drone frames on-site, slashing logistics delays by 70%. This agile modelexemplifies how open-source hardware projectsleverage advanced machining for sustainable outcomes.

Conclusion

Integrating 5-axis CNC machiningwith software-driven workflows eliminates prototyping bottlenecks, reducing lead times by 30% through automated programmingand single-setup precision. By prioritizing API compatibility, transparent quoting, and certified suppliers, developers can transform manufacturing into a competitive advantage. This approach not only accelerates innovation but also ensures cost-effective scalabilityfor projects of any complexity.

FAQs

Q1: What file formats are best for 5-axis CNC machining programming?

A: STEP and IGES formatsare ideal as they retain 3D geometry data essential for multi-axis toolpaths. Using CAD/CAM softwarecompatible with ASME Y14.5 standards ensures dimensional accuracy, minimizing errors in G-code interpretation.

Q2: How long does it typically take to get a 5-axis CNC machining quote?

A: Most quotes are delivered within 24 hoursfor standard designs. API-integrated systems may provide instant estimates, but complex parts requiring ISO 9001 compliance checks might take slightly longer for thorough validation.

Q3: Can 5-axis CNC machining handle materials like titanium for aerospace parts?

A: Yes, with specialized cutting tools and cooling strategies, five-axis machining systems can efficiently process titanium alloys. Suppliers certified to the AS9100D aerospace standard can ensure that critical components meet the relevant standards.

Q4: What are the benefits of using an Industrial Automation API with CNC systems?

A: APIs enable real-time data synchronization, reducing manual coding errors and cutting iteration time by 30%. For example, RESTful APIsallow direct 3D model transfers to CNC controllers, streamlining end-to-end workflows.

Q5: How do I ensure quality when choosing a 5-axis CNC machining supplier?

A: Verify ISO 9001 or industry-specific certifications, review case studies, and assess DFM feedback quality. Partners offering project trackingand technical supporttypically deliver higher consistency, aligning withperformance benchmarks.