Let's face it: running an electrical business is a bit like juggling flaming chainsaws while riding a unicycle. You've got crews to dispatch, clients to please, and materials to order, all while ensuring you don't zap your profits into oblivion.

And here's the kicker: often, you're losing money not because you're bad at wiring a house (you're a pro, obviously), but because of a sneaky little villain called a lack of job cost tracking.

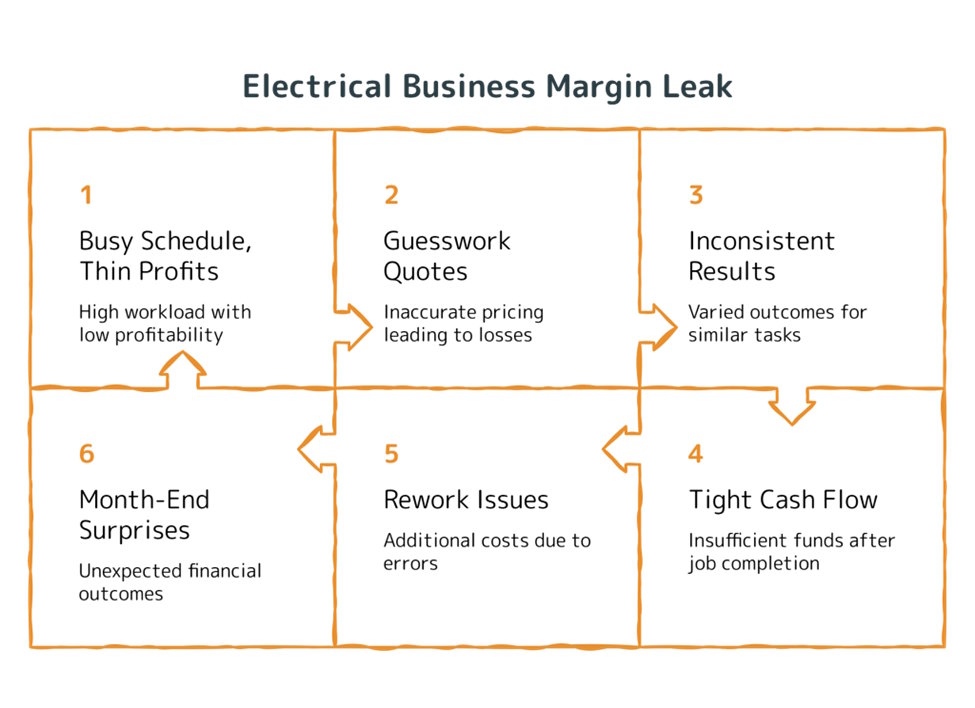

On the surface, everything looks peachy. The phone is ringing off the hook, your trucks are rolling out every morning, and revenue is coming in. But when you look at your bank account at the end of the month, you're left scratching your head, wondering, "Where did all the money go?"

If this sounds familiar, grab a coffee (or something stronger) and let's chat. Because the silent killer of your profit margin isn't a recession or a competitor; it's operating blind.

The Illusion of "Busy Equals Profitable"

We've all been there. You look at the schedule board, and it's packed tighter than a sardine can. You think, "Man, we are crushing it this month!"

But here's a hard truth: busyness is not the same thing as profit. Without tracking job costs, you're basically running your business on vibes. You rely on your gut instead of cold, hard data.

You might have a job that looks like a goldmine on paper, but in reality, it's leaking money faster than a punctured hydraulic line. The danger? These losses are invisible. They don't show up until weeks later when payroll hits or you realize cash flow is tighter than a new pair of boots. By then, the job is done, the customer is happy, and your profit margin is... well, gone.

Labor Overruns: The Ninja Assassin of Margins

Let's talk about labor. It's your biggest cost, right? And even tiny overruns can stack up like dirty laundry.

Picture this: you estimate a panel upgrade will take eight hours. Your crew takes eleven. Maybe they hit traffic, or maybe they spent 45 minutes debating the best sandwich shop in town. If you aren't tracking costs per job, those extra three hours just disappear into the weekly payroll void.

You pay the crew, the customer pays the invoice, and nobody flags the issue. Now, multiply that by five jobs a week. That's 15 hours of labor you paid for but didn't plan for. That is money straight out of your pocket.

When you don't track hours against specific jobs, you can't answer the simple stuff:

- Which types of jobs are we always slow on?

- Is Crew A actually faster than Crew B, or just louder?

- Are my estimates way too optimistic?

Tools that connect time tracking to work orders, like Field Promax, make these overruns stand out like a neon sign before they become a habit.

Pricing Based on "Hope and a Prayer"

How do you price your jobs? Do you look at past data, or do you just lick your finger, stick it in the wind, and guess?

Many folks price based on what the other guys are charging or what they feel is right. But pricing without job cost data is just expensive guesswork. You might be underpricing those complex troubleshooting gigs because they "feel quick," but you're forgetting the three return trips and the hour spent on the phone with tech support. Or maybe you're overpricing simple installs and losing bids left and right.

Job cost tracking gives you feedback. You see exactly what a job cost you, so your next quote is accurate. It's like having a cheat sheet for profitability. Without it, every quote is a gamble, and the house always wins eventually.

Death by a Thousand Papercuts (Inefficiencies)

Here's the thing about losing margin: it's rarely one giant, catastrophic explosion. It's usually a dozen tiny things that go wrong.

- Extra time on-site waiting for access.

- An unplanned trip to the supply house because someone forgot wire nuts.

- Redoing work because the instructions were written on a napkin.

Individually, these are annoyances. Collectively, they are profit killers. When you aren't tracking job costs, these little inefficiencies are invisible. They don't get brought up in the Monday meeting because there's no data tying them to a specific job.

But with visibility, you can spot patterns. "Hey, why does every job in the downtown district run 20% over budget?" Oh, it's because parking is a nightmare. Maybe we should charge for that?

Callbacks: The Ghost That Haunts Your Wallet

Callbacks are the worst. A technician has to go back to fix something; you can't charge the customer, but you still have to pay the tech.

Without job cost tracking, a callback is just another annoying task on the calendar. It's not tied to the original job, so you never see the true cost of that project. But when you track callbacks against the original work order, the picture gets clear. You might realize that one specific tech needs more training on installing that specific brand of breaker, or maybe you're buying cheap parts that fail too often.

This is where a system like Field Promax saves your bacon. It keeps the history together so callbacks don't just disappear into the noise; they stand out so you can fix the root cause.

Comparing Crews (Without Playing Favorites)

We all have that one crew we think is the best. But are they? Without data, you can't compare:

- Residential vs. commercial jobs.

- New installs vs. service calls.

- The "A-Team" vs. the new guys.

Everything just blends into a monthly report soup. That makes it hard to reward the efficient workers or coach the ones who are struggling. Job cost tracking turns performance into something you can measure, not just something you argue about.

Too Little, Too Late

The biggest problem with poor visibility is timing. By the time you realize your margins are slipping, the ship has sailed. The checks are cashed, payroll is done, and the money is gone.

Job cost tracking lets you course-correct while the work is actually happening.

- Job running long? You see it on Tuesday, not next month.

- Labor hours spiking? You can intervene.

- Estimates consistently off? Fix it before you quote the next big project.

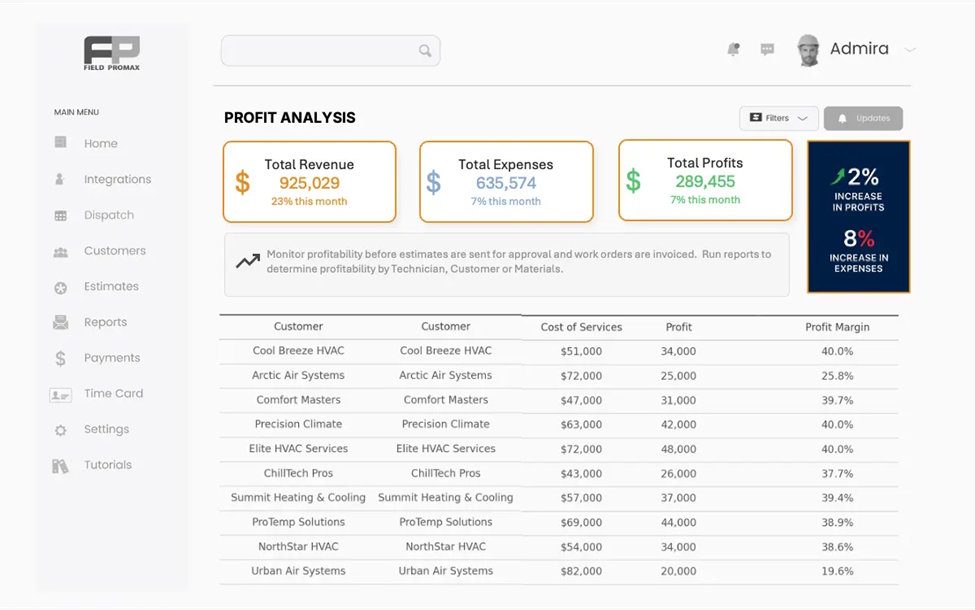

You need a central system to see this stuff without spending your weekends buried in spreadsheets. That's why smart electrical businesses use Field Promax. It puts scheduling, time tracking, and job data in one place, so you can stop guessing and start knowing.

The Bottom Line

Losing your profit margin isn't some big, dramatic event. It's more like a slow leak, dripping away with every misquoted job, every extra hour of labor, and every little mistake.

Tracking your job costs isn't about transforming into a spreadsheet-obsessed micromanager. It's about getting some clarity! It's about knowing that when you send that $5,000 invoice, you're actually banking a profit, not just generously donating to your customer's renovation fund.

So, are you ready to stop fumbling around in the dark? It's time to turn the lights on (pun absolutely intended) with some solid job cost tracking. Your bank account will be your biggest fan.

Frequently Asked Questions

What exactly is job cost tracking?

Think of it as a scoreboard for every single project. You track the labor hours, materials, and expenses for a specific job. This lets you compare what you thought it would cost, your estimate vs. what it actually cost.

Is this only for big companies with fancy accountants?

Nope! In fact, small and mid-sized businesses need it even more. When you're smaller, a few bad jobs can really hurt. Tracking costs helps you spot problems early so you can scale up without losing your shirt.

How does software help with this?

Software like Field Promax acts like a digital brain for your business. It connects time tracking, work orders, and job history all in one app. You don't have to do extra math; the system does it for you. It helps you see labor costs by job, find patterns, and fix pricing before margin loss becomes your new normal.